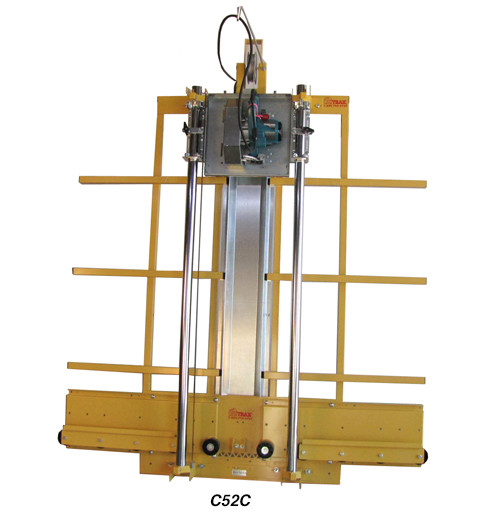

Saw Trax Classic Series Vertical Panel Saws

The Classic Series was developed as a lower price point panel saw for an apples-to-apples comparison with the bare bones panel saws that are on the market. They have identical accessories and price points. The differences are the standard features that come with each panel saw. When these are compared, we feel there is "still no comparison" and your choice will be the Saw Trax Machine. Accessories can be purchased as needed instead of the bundled accessory packages we offer in other models. This is the choice of the user who wants what he wants and not what we think he should have. Models come in Compact frames with 52" and 64" cross cuts and Full Size frames with 52", 64" and 76" cross cuts. All models use the Makita 5007F saw.

The Accu-Glide system uses 12 steel sealed bearings, 3 on each corner of the carriage. They are arranged 2 on top and 1 on the bottom to gently squeeze the steel guide tube ensuring a smooth and precise draw down of the saw. Other saws use a U-bolt with nylon washers as their bearing system. The problem with that system is the tighter you get them to take the play out of the carriage, the harder it is to move the carriage.

The Accu-Square indexed alignment system is our patented system to easily square the panel saw for a set and forget alignment. Below and between the center material rollers, you will see a series of 9 holes in the bracket holding the guide tubes. These holes are spaced 9/32″ apart with the 5th hole being centered. In the frame behind it are 9 holes, spaced 8/32″ apart with the 5th hole being centered. By shifting the bracket in relationship to the frame in 1/32″ increments, a different hole lines up with the hole in the frame. This way a sheet metal screw acts as an alignment pin locking the bracket to the frame once the machine is aligned. Sounds complicated but you don’t have to worry about it. All that you need to know is the guide tubes will never shift on you getting your saw out of alignment so it will always cut square. The other guys have a 3 page alignment process that includes whacking your guide tubes with a dead blow mallet and repeatedly running the saw up and down to see if you whacked it the right amount or too much. (Not very precise). There is no way to lock the bracket in place once you whacked it right so keep that dead blow mallet handy.

The Accu-Fence system is used on our full-size machines to ensure the rollers of the left fence line up with the rollers on the right fence. It uses a similar indexed alignment system to incrementally line up the outside of the right fence with the left fence. It is done at the factory and is set and forget so you don’t have to worry about it. The other guys weld their fences to the frame and have to make up for the alignment issues when the welds cool. To do this, they use the outside rollers as guides and all the interior rollers are on cams so they need to be adjusted up or down to correspond with the outside rollers. Not so simple; their instructions have you removing the stand, laying the machine on a table and using a 10 ft. straight edge on their 10 ft. wide models to align all of the rollers. The problem is no one makes a 10 ft. straight edge so you need to make one yourself. Once you have the wheels aligned, you will need to make a squaring tool also. That is why their Owner’s manual has a 3-page squaring process.

Standard Equipment

- Powder coated frame

- Zinc guide tubes

- Accu-Glide sealed bearing system

- Quick Release Carriage System

- Retraction Mechanism

- Cord Holder

- Center material support step

Package Includes

- Makita 5007F saw

- Spinning saw insert plate

- Dust containment hood

- Single horizontal measuring system

- Single vertical measuring system

- Makita Saw Blade

For More Saw Trax Products Click Here