Evans Coating Stripcoat, Types - I, II & IV

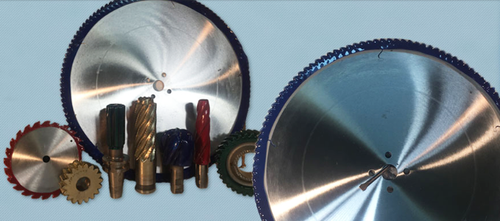

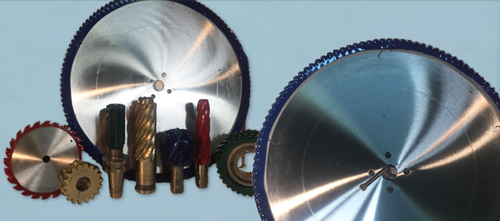

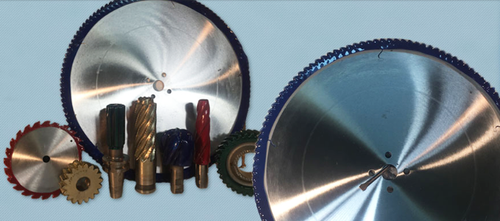

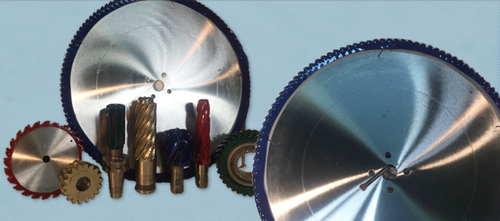

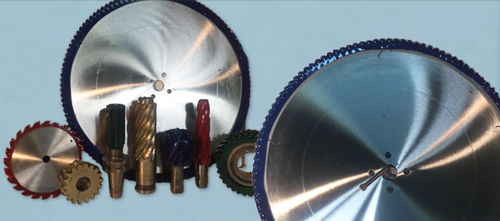

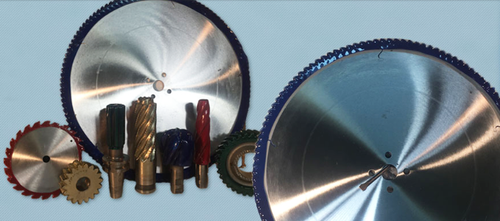

All Type I coatings are based on Ethylcellulose. These protective coatings contain mineral oil and are designed to leave an oil film on the protected part. These hot melt dip coatings provide the most corrosion prevention for long-term storage and protection against severe forms of abrasion and rough handling. Type I hot melt coatings are the easiest coatings to remove from parts. These protective tool coatings can be used to protect many types of cutting tools, saw blades, gages, end mills, gears, reamers, router bits, and various other parts.

All Type II versions of Evans Stripcoat are based on a material called cellulose acetate butyrate. These protective strippable coatings can be used for many different applications including protecting saw blades, end mills, gages, gears, router bits, reamers, and many other parts.

Oil-free, Type II coating used as a stopoff in electroplating, for capping ends of tubing, and sealing ends of electric cables. Meets the requirements of MIL-P-23242B.

- Suitable for chromium, copper, cadium, nickel and all common plating solutions

- Easy to apply – dip the part and its ready to trim in seconds

- Excellent adhesion for distinct stop-off lines

- Nontoxic, safe to use

- Saves time and eliminates painting or taping

- Easily removed and can be remelted and reused

Mask Peel is used in masking for electroplating and for sealing the ends of electric cables. Type II versions of Evans Stripcoat are the most durable and have the quickest setup time compared to other types. Our Type II coatings contain more odor than our other types of coatings. These hot melt dip coatings are easy to peel off and have a very long pot life.

Mask Peel is a simple, economical and effective process for many stop-off plating jobs

1 The part shown required the small arm and holes to be plated without plating the remaining surfaces. After heating mask peel to a molten state, the part is dipped in the compound for 1 to 2 seconds, removed and allowed to harden. Mask Peel hardens in approximately 5 minutes. the speed of hardening can be increased by dipping in cold water.

2 Mask Peel is approximately one tenth of an inch thick. the holes and arm are now easily trimmed with a razor or knife. This operation saves many hours of taping or lacquer painting and drying time. The part is ready for plating.

3 After the plating operation, mask peel can be peeled off as you would a banana.

4 Now the part is ready for assembly. After rinsing in water, Mask Peel can be remelted and reused.

All Type IV coatings are based on thermo-plastic rubber. These protective strippable coatings have a low operating temperature, no odor, and no messy oil residue. They are the softest of the Evans Stripcoat protective coatings yet are flexible enough to absorb shock and damage during handling Type IV coatings are less expensive than other types of dip coatings. These coatings are most affected by high temperature. Type IV protective coatings can be used as a protective sawblade coating and as a protective cutting tool coating and on various other small parts.